LABORATORY OF MACHINING

Laboratory of Machining

05 November 2024 TuesdayDevices in Laboratory Inventory

1. CNC Vertical Machining Center

CNC machine tools offer advantages like high efficiency and part quality, easy quality control, reduced need for additional apparatus and storage, and the ability to perform multiple operations in a single setup. With fixed operation times, production planning, monitoring, and control are straightforward, and the ability to predict time and cost provides flexibility in design and operation.

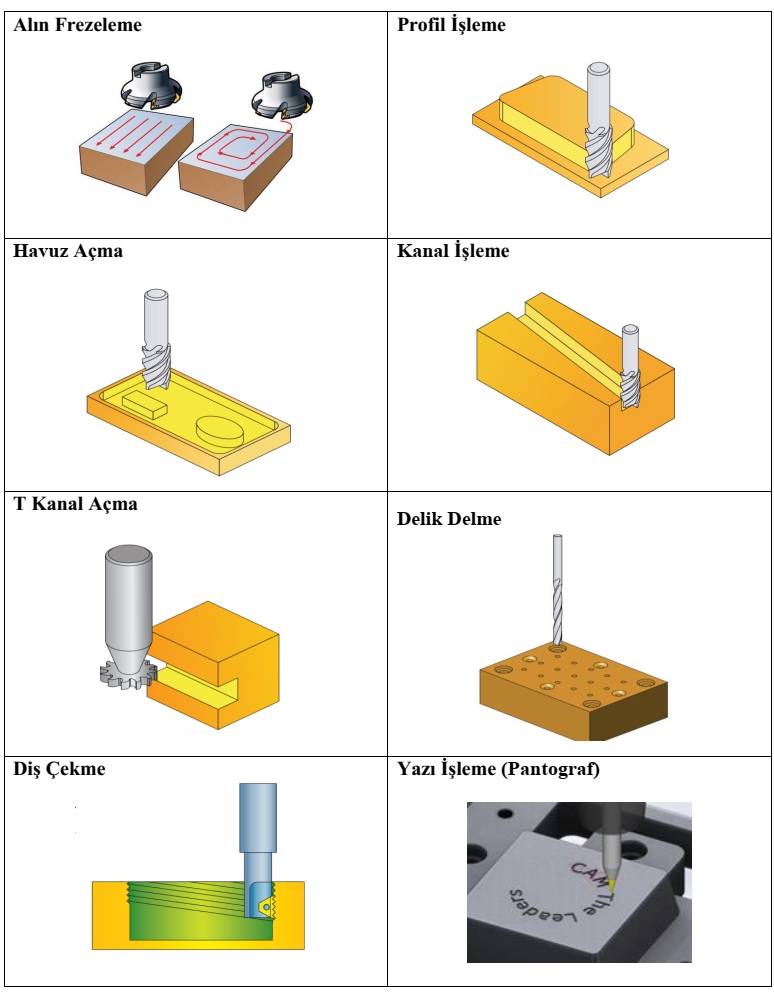

In our department, we have one DMG Mori Seiki DMC 635 V Ecoline CNC Milling Machine. Operations that can be quickly performed with the help of our technician are listed below. The technical specifications of our CNC milling machine are as follows:

- X-Axis Travel: 635 mm

- y-Axis Travel: 510 mm

- z-Axis Travel: 460 mm

- Spindle Speed (max): 8000 rpm

- Torque (max) (40 / 100% DC): 83 / 57 Nm

- Spindle Power (40 / 100% DC): 13 / 9 kW

- Tool Capacity: 20 adet

- Table Load Capacity (max): 600 kg

[ 1 ] Solidcam 2009 Milling User Guide, Solidcam, 2009.

2. CNC Lathe

CNC lathes are used for manufacturing cylindrical (rotational) workpieces, similar to conventional lathes. Unlike NC machines, CNC machines allow for program interruption, modification, and storage of modified programs. Tool parts, dimensions, and other parameters can be defined in the control unit by the operator, and only need to be set once. CNC machines operate without operator intervention during part processing, minimizing human error and enhancing safety.

In our department, we have one DMG Mori Gildemeister CTX Alpha 300 CNC Lathe. Its technical specifications are as follows:

- Maximum Turning Diameter: 200 mm

- Maximum Turning Length: 335 mm

- Spindle Speed (max): 6000 rpm

- Torque (max): 127 Nm

- Tool Capacity: 12 tools

3. Universal Lathe Machine

We have one Jetco JML-3610W Universal Lathe Machine. The specifications are as follows:

- Swing Over Bed: 356 mm

- Swing Over Carriage: 216 mm

- Swing in Bridge Gap: 508 mm

- Bed Width: 267 mm

- Distance Between Centers: 1015 mm

- Spindle Nose: D1-4

- Spindle Bore: 38 mm

- Spindle Taper: MT-5

- Spindle Speed Range: 12

- Cross/Compound Travel: 40 – 1800 rpm

- Tool Size: 162/89 mm

- Metric Thread Range: 0.04 – 0.6 mm/devir

- Tailstock Quill Travel: 120 mm

- Motor Power: HP 5.7 / S6 %40

- Dimensions (LxWxH): 1873 x 750 x 1200 mm

- Net Weight: 995 kg

4. Drill Press

We have one Jetco JDGP-35 Gear Head Drill Press, capable of drilling up to 35 mm holes and tapping up to M22. Its specifications are:

- Maximum Drilling Capacity: 35 mm

- Maximum Tapping Capacity: M22

- Maximum Stroke: 190 mm

- Maximum Distance Between Spindle and Column: 360 mm

- Maximum Distance Between Spindle and Table: 615 mm

- Maximum Distance Between Spindle and Base: 1195 mm

- Spindle Taper: MT4

- Speed Range: 72 – 2580 rpm

- Table Dimensions: 570 x 480 mm

- Column Diameter: 140 mm

- Main Motor Power: 2 kw

- Dimensions: 1000 x 650 x 2220 mm

- Net / Gross Weight: 565 / 615 kg

5. Saw Machine

Our Beka-Mak BMSO 320 Saw Machine is suitable for quick cutting of workpieces to desired lengths. It is a fully automatic bandsaw capable of cutting solid material, pipes, cast steel, steel, and similar metals. The technical specifications are as follows:

- Round Cutting Capacity: 320 mm

- Square Cutting Capacity: 300 mm

- Main Motor: 2,2 kW

- Hydraulic Motor: 0,37 kW

- Cooling Motor: 0,12 kW

- Cutting Speed Range: 20 – 100 m/min

- Weight: 770 kg

- Dimensions: 1900 x 850 x 1300 mm

6. Tensile and Compression Testing Machine

The Shimadzu AG-IC 100kN Tensile-Compression Testing Machine in our department is used to perform tensile tests, one of the oldest and most widely used mechanical tests for metals, alloys, polymers, ceramics, and composites. This device is essential for evaluating materials' mechanical properties during design, comparing materials, and predicting material behavior in service conditions. The device can apply loads up to 100 kN.